PVC/WPC Door panel/Door frame Production Line

In recent years, WPC wood-plastic doors, as an emerging environmentally door products, have attracted more and more attention from consumers. They are very popular among customers because of their environmental protection, waterproof and moisture-proof, corrosion resistance, fireproof and other advantages. It is also widely used in the decoration of bedrooms, bathrooms, kitchens, villas, residences, hotels, schools, hospitals, etc, which has a bright prospect.

WPC Door panel examples:

WPC Door frame examples:

The equipment used to produce WPC wood-plastic door panels and frames has become the first choice of many manufacturers. The production line consists of a conical twin-screw extruder, a vacuum shaping platform, a tractor, a cutting machine, and a auto stacker. The production line has reliable performance and high production efficiency. The material is made of PVC mixed with wood powder. It can produce door panels and frames with a width of 700-1100mm and a thickness of 15-50mm. The surface can be coated, engraved, spray-painted, embedded in glass and other designs.

Production process flow and video of WPC door panel and door frame equipment:

- Use a wood chipper to slice the wood, then use a grinder to grind the wood chips into wood powder, and use a dryer to dry the wood powder for easy use.

- Use a mixer to mix wood powder and PVC powder.

- Feed the mixed raw materials to the extruder through the hopper

- Shape the door panel and frame preliminarily through the extrusion mold and the shaping mold.

- The door panel and door frame are cooled and dried through the shaping platform to shape more nice.

- The shaped door panel and frame are pulled by a tractor

- Cut door panels and frames according to customer needs

- Sand the cut door panels and frames with a sander to make the surface smooth.

- Use a laminating machine to laminate the polished door panels and frames.

- If the door panel needs to be engraved, can use an engraving machine to engrave it first.

- Then use a vacuum laminating machine to vacuum laminate the door panel to make it more beautiful.

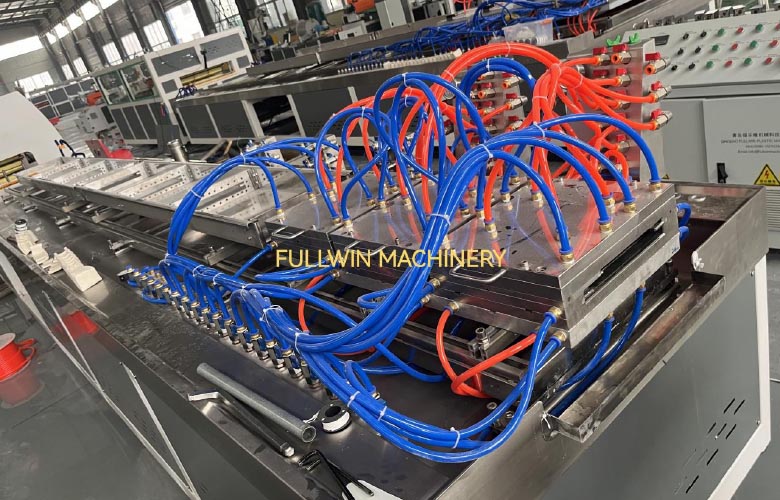

FULLWIN MACHINERY WPC/PVC Door panel/frame production machine shows:

WPC/PVC door panel/frame auxiliary machine shows:

wood chipper:

wood milling machine:

wood powder dryer:

Hot and cold mixer:

sander:

Laminating machine:

Engraving machine:

Vacuum laminating machine: