PVC UPVC window door frame profile production line

PVC profile application:

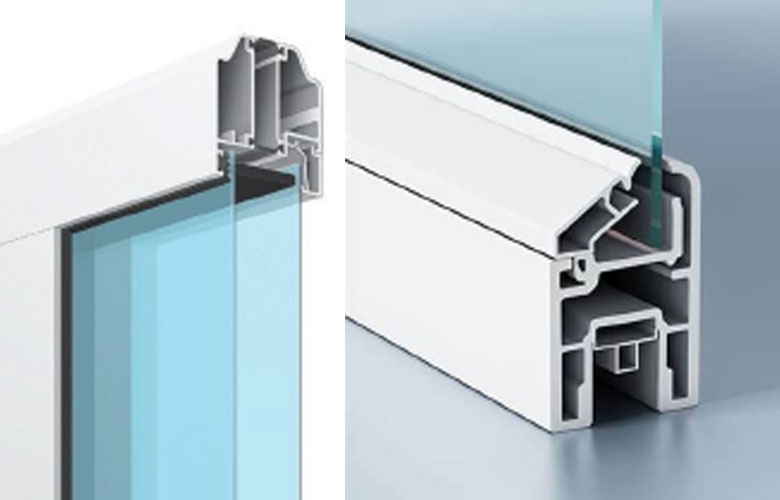

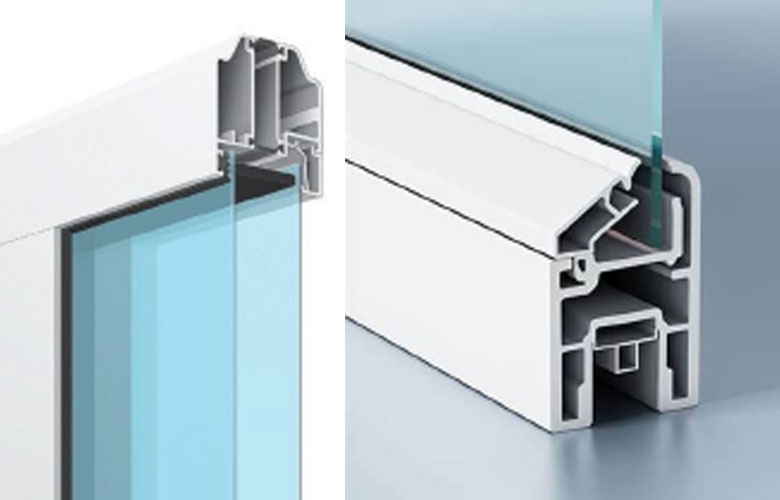

PVC special profiles refer to PVC products made of PVC materials and extruded through irregular-shaped molds. This profile is usually used to make window frames, door frames, curtain tracks and other fields.

As the picture shows:

According to the statistics,In developed countries, the market share of plastic doors and windows ranks first, such as 50% in Germany, 56% in France, and 45% in the United States.so the PVC window and door frame profiles has big market.

Composition of production line:

1. Double screw extruder

2. Extrusion moulds and sizing moulds

3. Vacuum sizing platform

4. Hauling off and cutting machine

5. Stacker

PVC profile Crafts flowing chart:

Raw materials→mixer→loader→extruder→extrusion mould→vacuum sizing platform

→hauling off machine→cutter→stacker

Our machine advantages:

- The extrusion mould will be designed one time two pcs out or one time four pcs out according customer requirements,in this way can greatly increase production for customer.

- Screw adopt 38CRMOAIA material, high wear resistance and hardness

- Mold can be designed according to customer’s sample and drawing,high quality

- Die head heating ring adopt our new design ,energy-saving heating ring can help customer save about 30% electricity cost.

- Delta converter,Omron temperature control.Siemens air switch,All the parts using domestic and foreign well-known brands.