PVC Corner Bead Production Line

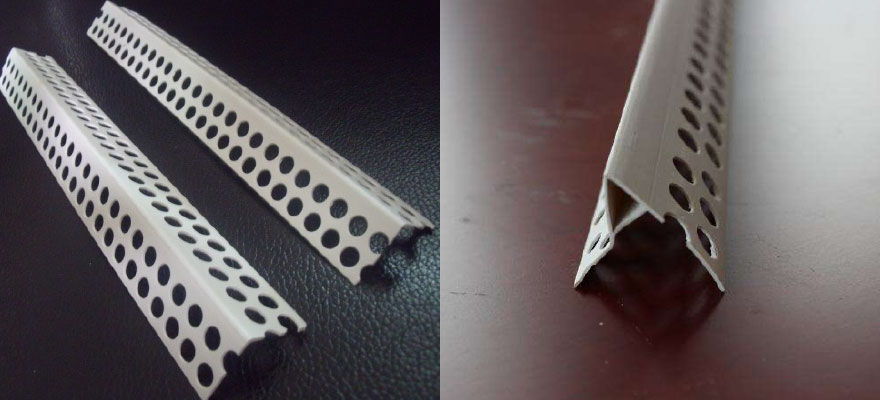

PVC corner bead is a new type of decoration material for the wall corners, door side strips, and window corners. It is made of high strength PVC raw materials and has good corrosion resistance, impact resistance, aging resistance and weather resistance. Its strength and toughness have made people safely replace various traditional building materials such as steel, wood, aluminum, etc.

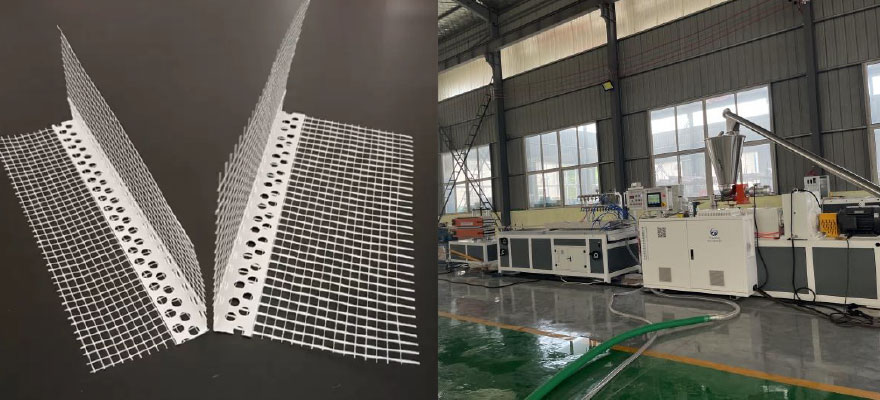

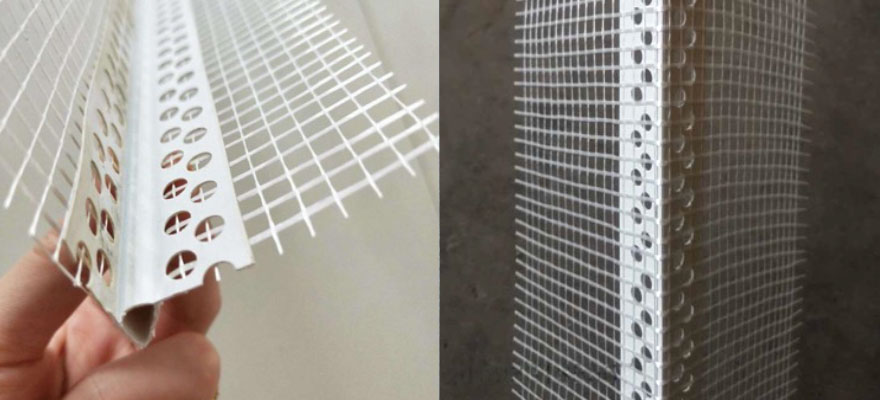

PVC corner bead mesh is mainly made of PVC corner bead, and covered with glass fiber mesh as a whole. It is usually used in the corner of the external wall insulation system. During the use of PVC corner bead mesh, there is no need to use a ruler board. It is easy to operate and the construction efficiency is about 2 to 5 times, which effectively reduces the engineering cost and improves the strength, beauty and strength of the corner.

In building construction, there have been common quality problems such as uneven corners, unsightly appearance, and easy damage for a long time. The use of PVC corner bead mesh in interior and exterior wall insulation can effectively solve these common problems of uneven corners, unevenness, and easy collision damage.

SJSZ-51/105 double screw production line use powder directly, without granulation, FULLWIN corner bead production line technology, compact structure, easy to operate.

The production line can replace molds to produce PVC building corner bead, corner strips, external corner strips, interior corner strips, exterior wall insulation system corner bead and other products. Cooperate with the mesh covering machine to make the glass fiber mesh Bonded to corner bead for use in external wall insulation systems

Equipment composition:

1. Conical Double Screw Extruder (also can use single screw extruder as to customer requirement)

4. Vacuum calibration and cooling table

5. Haul off machine

6. Online punching machine

7. Cutter and counting profiles

8. Automatic mesh covering machine

Equipment advantages:

1. Extrusion by twin-screw/single-screw main machine, no need granulation, and PVC powder is directly used for extrusion.

2. More than one mold can extrude multiple corner guards at the same time,

3. Electromagnetic heating, power saving, energy saving,

4. The equipment has a high degree of automation and is easy to operate.

5. Fast setting speed, energy saving, high output,

6. Online automatic punching, one-time completion, reducing process and labor cost