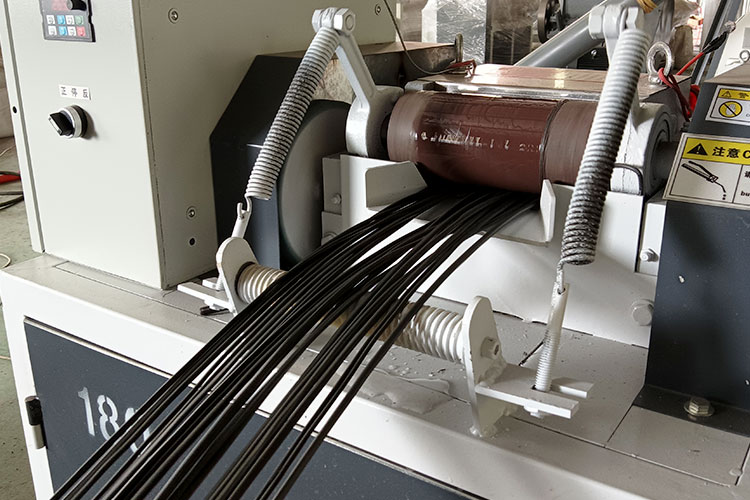

PVC Granulator Machine

This type kind of PVC Granulator Machine is specially designed by Fullwin to help clients fully recycle the waste material. By means of high-quality screw and efficient auxiliary machines. This whole production line can satisfy nearly all the clients’ needs to make final granules.

Main Features:

- 1. Suitable for making PVC granules.

- 2. Raw Material: PVC waste material after being crushed.

- 3. Production capacity: 450-500kg/h.

- 4. Main parts: Spiral feeder, Twin screw extruder, Extrusion die head, Air cooling cutting device, Material conveying system.

- 5. Professional suggestions about the formula and the surface PVC marble sheet will be provided.

Our Advantages:

- 1. New technology gear box: High torque gear box, one body design, two cooling system.

- 2. Screw and barrel: Bi-metal material ensure longer working life, ensuring running non-stop 24 hours /day.

- 3. Energy saving heater: Heater on the barrel is energy saving type by 15%.

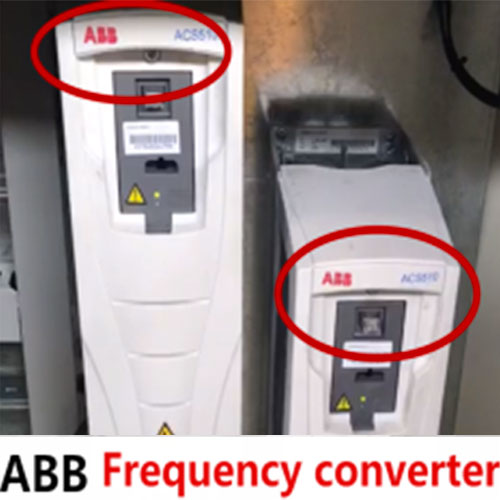

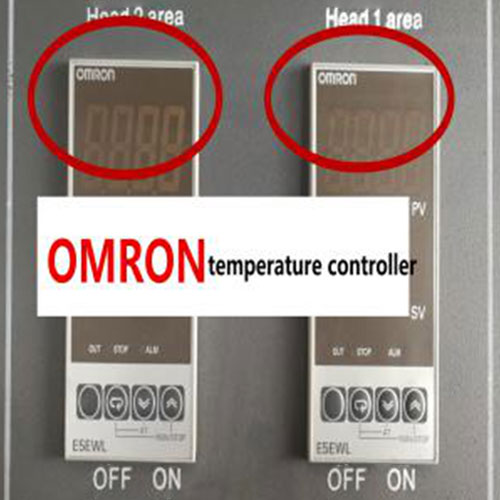

- 4. Electric elements and box: In detachable, with world famous brand such ABB, Siemens, Schneider, Delta, well organized.

- 5. PLC control system: With operation easy, management full, energy saving and counting, and intelligent control system.

Main Technique Parameter:

No. | Description | Parameter |

1 | Raw material | PVC waste material |

2 | Production capacity | 450-500kg/h |

3 | Heating power | 24.8KW |

4 | Motor power | 75KW |

5 | Air consumption | 0.4m³/min |

6 | Air pressure | 0.6mpa |

7 | Water circulation | 0.3m³/min |

8 | Power supply | 3P, AC400V±10%,50HZ |

9 | Source of water | Industrial water, free of impurities, filtered, water pressure: 4bar, water temperature 14~18°C |

10 | Working temperature | 0-40℃ |

Electric Parts:

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Our Service:

Pre-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

After-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

Packing & Deliery:

Stretch Film Packaging

Wooden Box Plywood Packaging