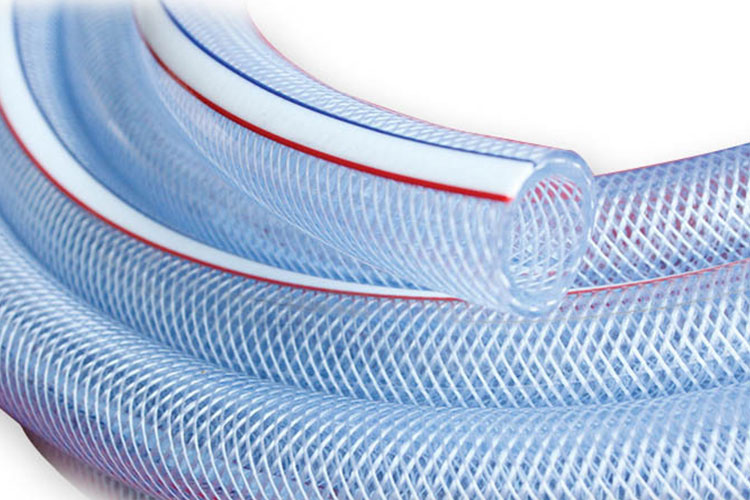

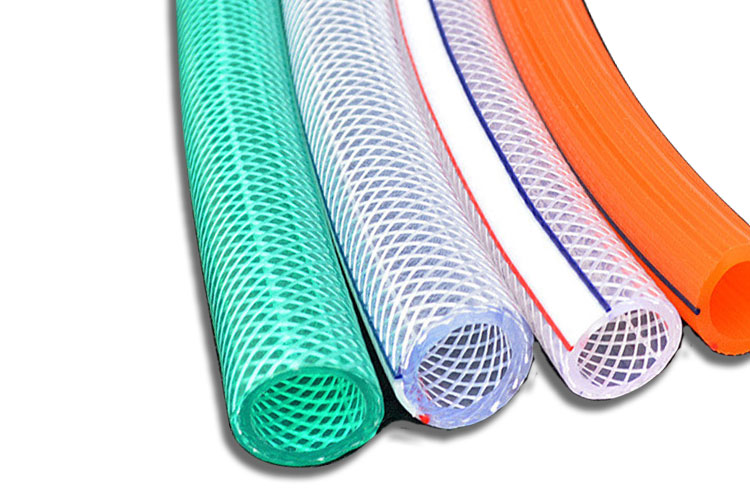

PVC Fiber Reinforced Hose Extrusion Line

FULLWIN series of plastic single wall corrugated pipe production line meticulously developed by our company, through the gear drive mould, water cooling in the water trough of the forming machine so that the production of the pipe molding speed, uniform corrugated shape, smooth inside and outside the wall. The production speed is 8-15 meters per minute.

Main Features:

- 1. Suitable to produce PVC fiber-reinforced hose/pipe extrusion.

- 2. Raw Material: PVC powder or PVC granules.

- 3. Production capacity: 60-80kg/h.

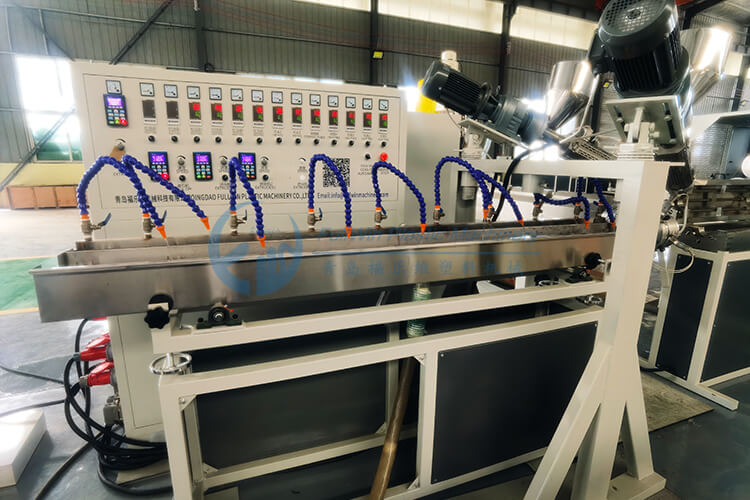

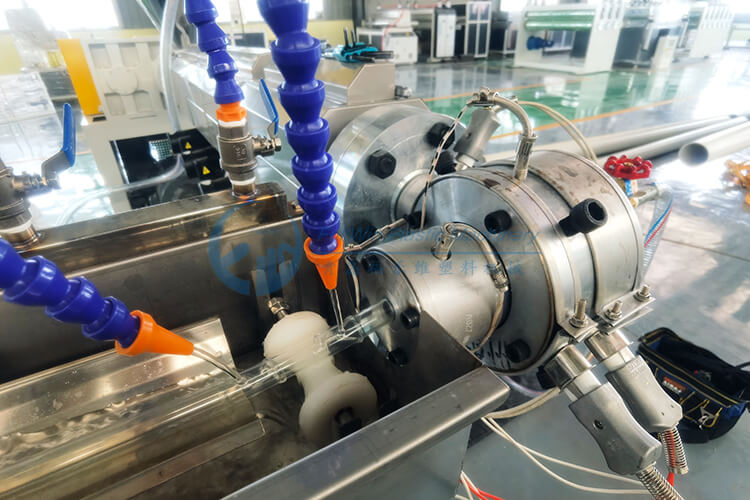

- 4. Mainly includes: Single Screw Extruder, Die head and Mould, knitting machine, Drying tank, Winder, Ink shift printer, Electrical cabinet.

- 5. Supply technical service, formula guide and staple raw material purchase.

Our Advantages:

- 1. The extruder has the following advantages: high plasticization rate, uniform melt and continuous production stability. High-performance gearbox reducer. High torque, long life and low noise.

- 2. Surface nitriding, After Nitriding, the product has excellent wear resistance, fatigue resistance, corrosion resistance and high-temperature resistance, and longer working life.

- 3. All parts are using domestic and foreign well-known brands.

Electric Parts:

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Our Service:

Pre-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

After-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

Packing & Deliery:

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging

CONTACT FULLWIN

Email: info@fullwinmachinery.com

Tel: +86 15254294721

Tel: +86 532 82207059

Address: Jiaozhou City, Qingdao, China.