PP/PE/PPR Compound Pipe Extrusion Line

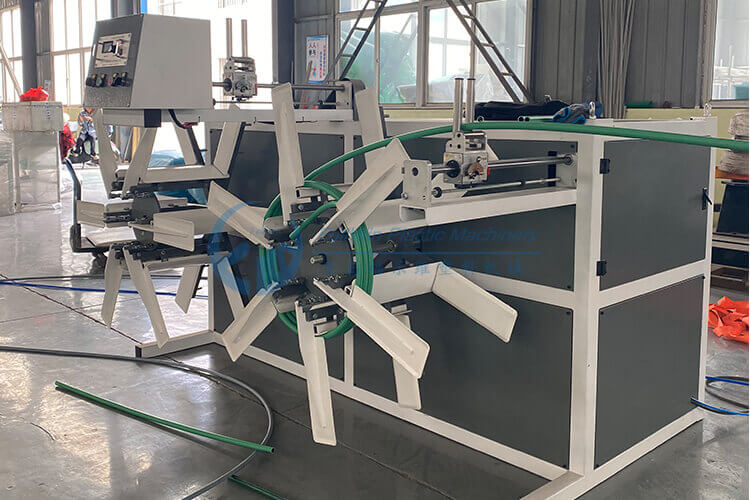

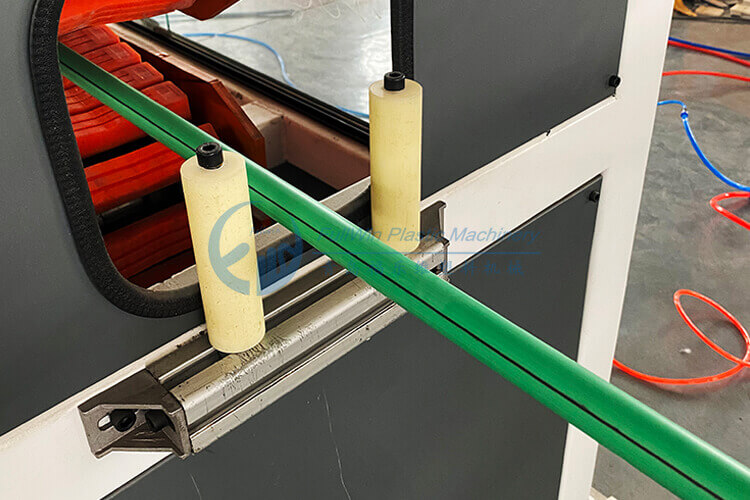

PP/PE/PPR pipe production line, can be used to produce PPR hot and cold water pipes, PE pipe, silicon core tube, the production line can be used to produce a single extruder monochrome tube, can also be used to produce multiple extruders through the co-extrusion head multi-layer color tube.

Main Features:

- 1. Suitable to produce PE PPR compound pipe extrusion.

- 2. Raw Material: PP PE PPR granule.

- 3. Production speed: 150-200kg/h.

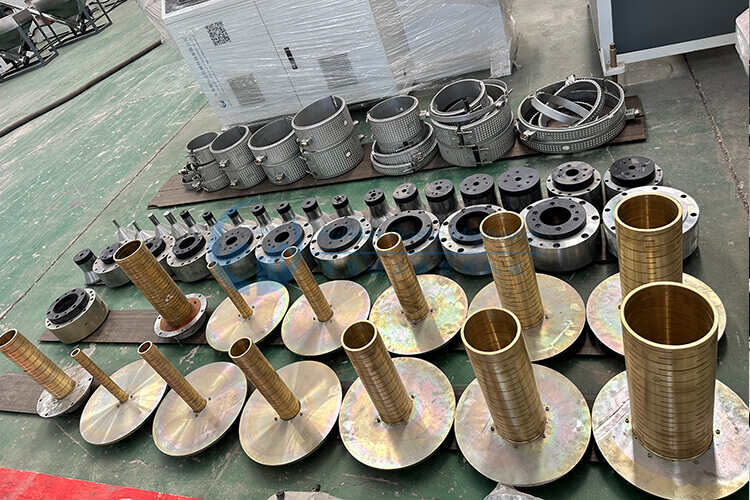

- 4. Mainly includes: Extrusion machine, Vacuum sizing water tank, Spraying water tank,Hauling off machine, Auto stacker, Crusher, Mixer.

- 5. Supply technical service, formula guide and staple raw material purchase.

Our Advantages:

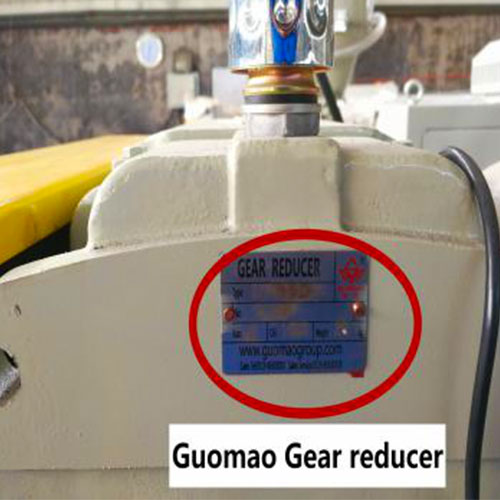

- 1. The extruder has the following advantages: high plasticization rate, uniform melt and continuous production stability. High performance gearbox reducer. High torque, long life and low noise.

- 2. Surface nitriding,After Nitriding, the product has excellent wear resistance, fatigue resistance, corrosion resistance and high-temperature resistance, and longer working life.

- 3. All parts are using domestic and foreign well- known brands.

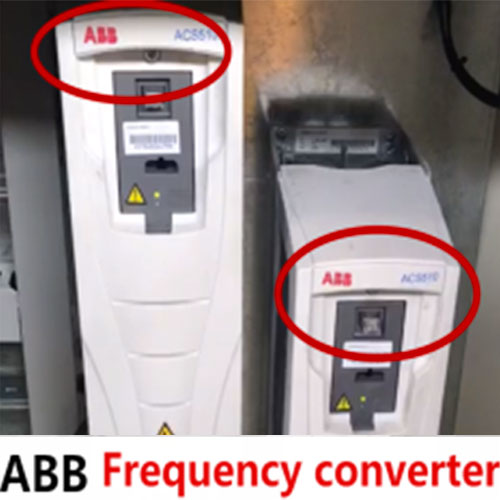

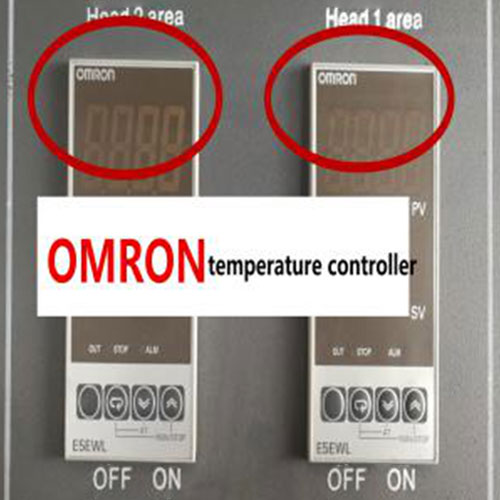

Electric Parts:

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Our Service:

Pre-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

After-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

Packing & Deliery:

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging

CONTACT FULLWIN

Email: info@fullwinmachinery.com

Tel: +86 15254294721

Tel: +86 532 82207059

Address: Jiaozhou City, Qingdao, China.