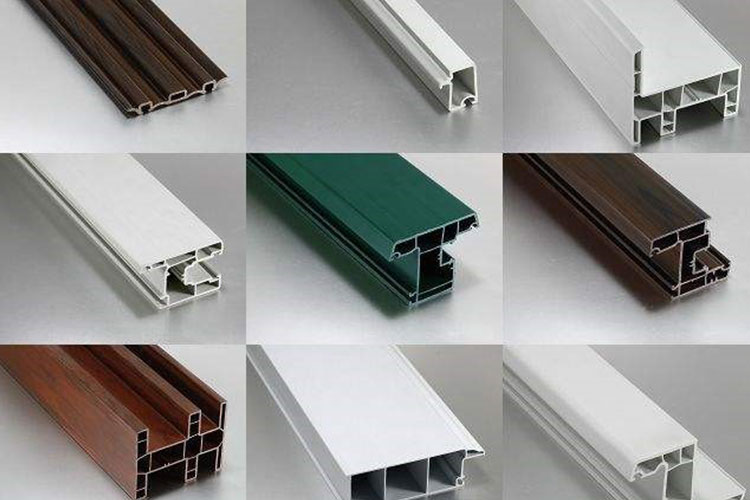

PP PVC Profile/Trunking Profile Machine

The PP PVC profile/trunking profile extrusion line includes 51/105 twin-screw extruder or 55/110 twin-screw extruder, extrusion die, shaping die, shaping platform or calibrator, tractor, cutting machine, unloading frame, etc…

Main Features:

- 1. Capacity: 80-150 kg/h.

- 2. Raw Material: PP granule PVC powder.

- 3. Used for internal wiring of electrical equipment and plays a role of mechanical protection and electrical protection.

- 4. The corner protection equipment can be extruded with a single-screw extruder or a twin-screw extruder according to customer requirements, and according different size can one time one piece or one time two pieces or one time four pieces

- 5. Mainly includes: 51/105 twin-screw extruder or 55/110 twin-screw extruder, extrusion die, shaping die, shaping platform, tractor, cutting machine, unloading frame, etc.

- 6. Supply technical service, formula guide and staple raw material purchase.

Our Advantages:

- 1. The production line is automatic control, with high degree of automation, stable equipment, simple operation and high production efficiency.

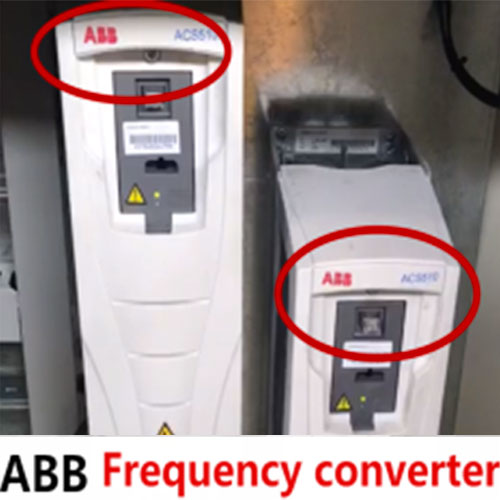

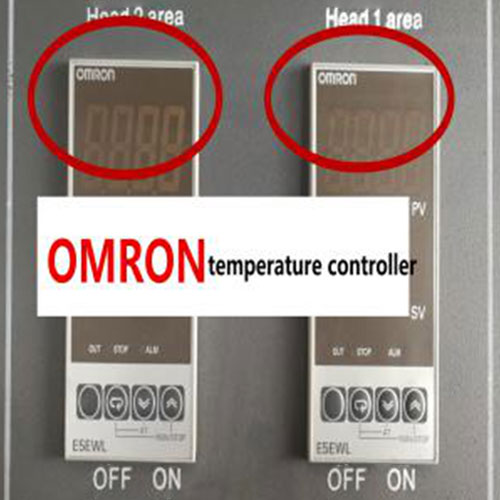

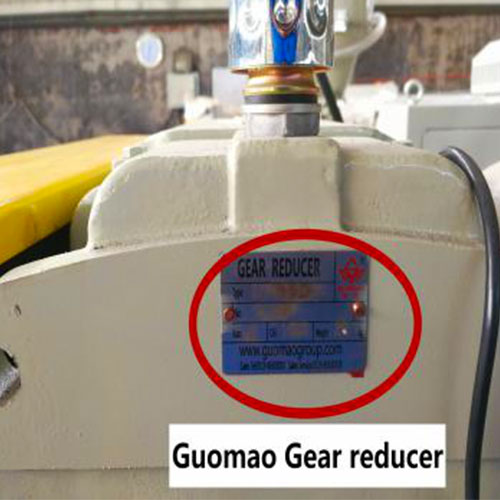

Electric Parts:

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Our Service:

Pre-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

After-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

Packing & Deliery:

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging

CONTACT FULLWIN

Email: info@fullwinmachinery.com

Tel: +86 15254294721

Tel: +86 532 82207059

Address: Jiaozhou City, Qingdao, China.