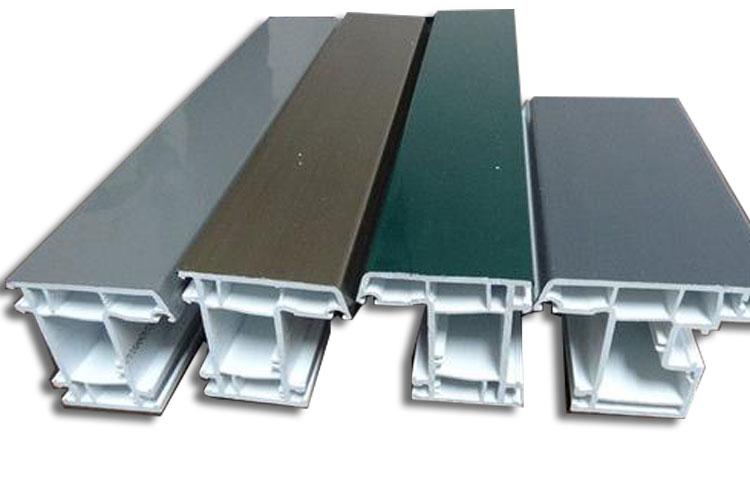

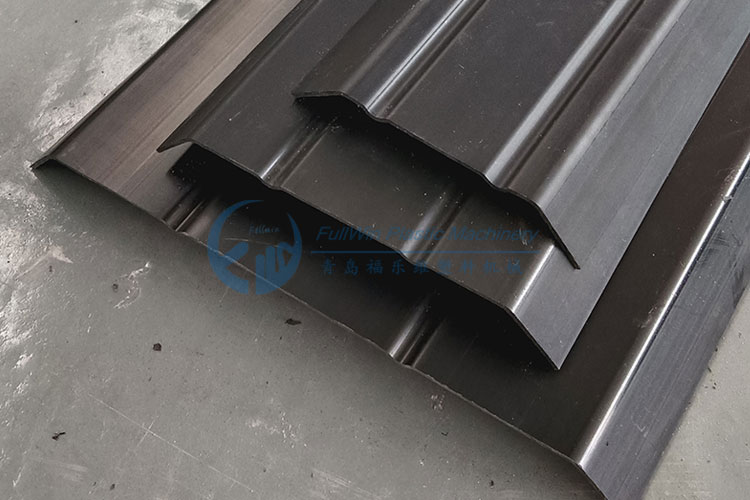

PVC Windows And Doors Profile Machine

The PVC windows and doors profile extrusion line includes: twin-screw extruder, molds, vacuum calibrator, hall off & cutter, and auto stacker. According customer different situation can also add the other auxiliary machines, like raw material mixer, crushing machine and pulverize machine for recycling.

Main Features:

- 1. Capacity: 100 - 300 kg/h.

- 2. Raw Material: PVC resin powder and other additions, like calcium, stabilizer etc.

- 3. According to different sizes, calibrator can custom design 4 meters, 6 meters, 9 meters, 11 meters.

- 4. Production line mainly includes: win-screw extruder, molds, vacuum calibrator, hall off & cutter, and auto stacker.

- 5. Supply technical service, formula guide and staple raw material purchase.

Our Advantages:

- 1. The tractor adopts our company's unique lifting technology, with stable operation, reliability and large tractive force.

- 2. The vacuum shaping adopts a special enlarged eddy current cooling system, which is convenient for cooling and shaping, so as to meet the needs of high-speed extrusion requirement.

- 3. The moving speed of the cutting machine and the traction speed are kept in synchronization, controlled by imported PLC computer. The design is reasonable and running is stable. It can cut automatically with fixed length and is equipped with dust collect device.

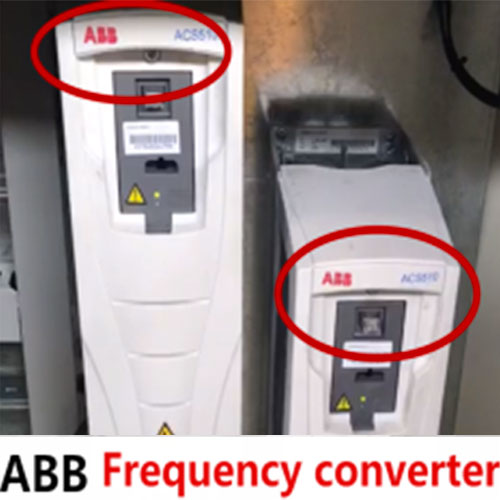

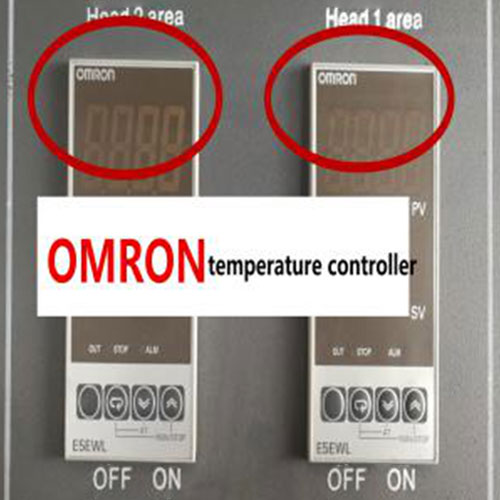

Electric Parts:

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

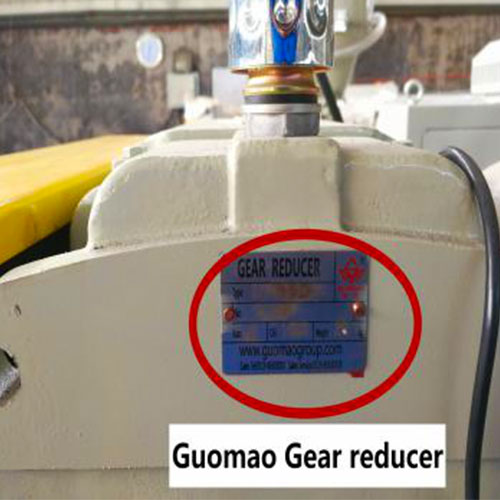

Guomao Gear Reducer

Our Service:

Pre-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

After-Sales Service

- 1. Online Inquiry and consulting support 24 hours.

- 2. Sample testing support.

- 3. View our Factory.

- 4. Whole manufacturing process traceable.

Packing & Deliery:

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging

CONTACT FULLWIN

Email: info@fullwinmachinery.com

Tel: +86 15254294721

Tel: +86 532 82207059

Address: Jiaozhou City, Qingdao, China.